Home / our Capabilities

our Capabilities

Click on each tab below to explore more details.

-

DESIGN AND 3D MODELING

-

LASER CUTTING

-

SHEET METAL FORMING

-

MACHINING

-

WELDING

-

FINISHINGS/COATINGS

/HEAT TREATING -

ASSEMBLY

-

QUALITY

DESIGN AND 3D MODELING

Centerline Mfg. can provide its customers with general design and design for manufacturing support. Through our use of computer-aided drafting technologies, we can assist you in a number of stages and processes through; prototype design, fixture design, final production and product revisions. By leveraging our use of computer-aided machining software, we will quickly and accurately program your components and assemblies for milling, turning and laser cutting for maximum efficiency in manufacture.

DATA EXCHANGE

3D Manufacturing Format (*.3mf)

FBX (*.fbx).

SAT/SMT Files (*.sab, *.sat, *.smb, *.smt)

Autodesk Alias (*.wire).

IGES (*ige, *iges, *igs).

Seimens NX (*.jt)

AutoCAD DWG Files (*.dwg).

NX (*prt).

SOLIDWORKS Files (*.prt, *.asm, *.sldprt, *.sldasm)

Autodesk Fusion Archive Files (*.f3d).

OBJ (*.obj).

STEP Files (*.ste, *.step, *.stp).

Autodesk Fusion Toolpath Archive Files (*.cam360).

Parasolid Binary Files (*.x_b).

STL Files (*.stl).

Autodesk Inventor Files (*.ipt, *.iam).

Parasolid Text Files (*.x_t).

SVG Files (*.svg)

CATIA V5 Files (*.CATProduct, *.CATPart).

Pro/ENGINEER Files (*.asm, *.prt).

TSM Files (*.tsm)

DXF Files (*.dxf).

Pro/ENGINEER Granite Files (*.g).

SketchUp Files (*.skp).

Electronics Board Files (*.brd)

Pro/ENGINEER Neutral Files(*.neu).

123D File (*.123dx).

Electronics Schematic Files (*.sch)

Rhino Files (*.3dm).

Creo Parametric Files (*.asm, *.prt).

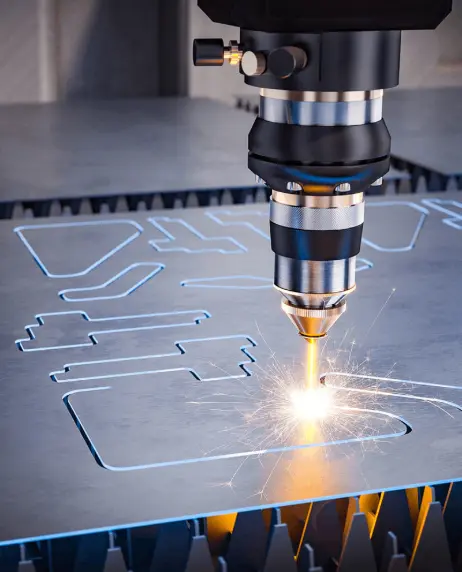

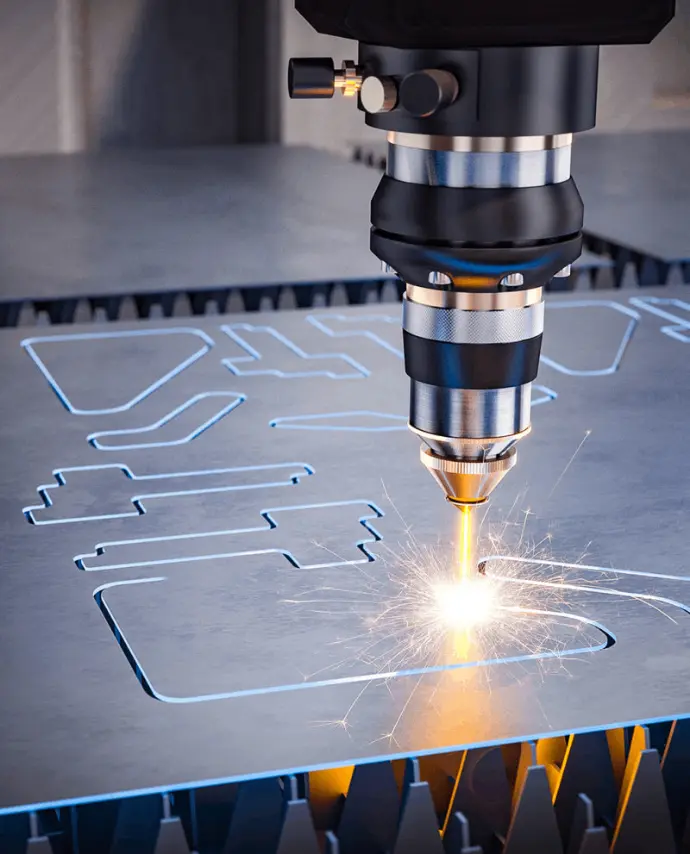

LASER CUTTING

Centerline

Mfg. utilizes Bystronic and Mazak laser cutting machines to produce

high-precision and high-quality sheet and plate parts from various materials.

EQUIPMENT

Bystronic - 6'x12' work envelope

Mazak - 5'x10' work envelope

MATERIALS

Mild Steel

High Strength (HSLA) Steel

Stainless Steel

Galvanized Steel

Aluminum (all grades)

Brass

Copper

Various Plastics

Wood Products

VOLUME CAPABILITES

From prototypes to high volume production into the millions of units annually, depending on complexity, material and

application.

SECONDARY OPERATIONS

Deburring

Tapping

Machining

Hardware Installation

Powder Coating

Catalyst and Non-Catalyst Paints

Heat Treating

Plating

Anodizing

Polishing

DATA EXCHANGE

3D Manufacturing Format (*.3mf)

FBX (*.fbx).

SAT/SMT Files (*.sab, *.sat, *.smb, *.smt)

Autodesk Alias (*.wire).

IGES (*ige, *iges, *igs).

Seimens NX (*.jt)

AutoCAD DWG Files (*.dwg).

NX (*prt).

SOLIDWORKS Files (*.prt, *.asm, *.sldprt, *.sldasm)

Autodesk Fusion Archive Files (*.f3d).

OBJ (*.obj).

STEP Files (*.ste, *.step, *.stp).

Autodesk Fusion Toolpath Archive Files (*.cam360).

Parasolid Binary Files (*.x_b).

STL Files (*.stl).

Autodesk Inventor Files (*.ipt, *.iam).

Parasolid Text Files (*.x_t).

SVG Files (*.svg)

CATIA V5 Files (*.CATProduct, *.CATPart).

Pro/ENGINEER Files (*.asm, *.prt).

TSM Files (*.tsm)

DXF Files (*.dxf).

Pro/ENGINEER Granite Files (*.g).

SketchUp Files (*.skp).

Electronics Board Files (*.brd)

Pro/ENGINEER Neutral Files(*.neu).

123D File (*.123dx).

Electronics Schematic Files (*.sch)

Rhino Files (*.3dm).

Creo Parametric Files (*.asm, *.prt).

SHEET METAL FORMING

Centerline Mfg. offers a variety of sheet metal forming services in various materials and thicknesses. From V and U bends to bump forming and hemming, we can meet our customers’ needs. We are also able to create prototype dies and punches for our customers’ specialty forming needs.

EQUIPMENT

Piranha,

185 Tons, max bend length 121", material and thickness dependent

MATERIALS

Mild Steel

High Strength (HSLA) Steel

Stainless Steel

Galvanized Steel

Aluminum (all grades)

Brass

Copper

Volume Capabilities

From prototypes to high volume production into the tens of thousands of units annually, depending on complexity, material and application.

SECONDARY OPERATIONS

Deburring

Tapping

Machining

Hardware Installation

Powder Coating

Catalyst and Non-Catalyst Paints

Heat Treating

Plating

Anodizing

Polishing

DATA

EXCHANGE

3D Manufacturing Format (*.3mf)

FBX (*.fbx).

SAT/SMT Files (*.sab, *.sat, *.smb, *.smt)

Autodesk Alias (*.wire).

IGES (*ige, *iges, *igs).

Seimens NX (*.jt)

AutoCAD DWG Files (*.dwg).

NX (*prt).

SOLIDWORKS Files (*.prt, *.asm, *.sldprt, *.sldasm)

Autodesk Fusion Archive Files (*.f3d).

OBJ (*.obj).

STEP Files (*.ste, *.step, *.stp).

Autodesk Fusion Toolpath Archive Files (*.cam360).

Parasolid Binary Files (*.x_b).

STL Files (*.stl).

Autodesk Inventor Files (*.ipt, *.iam).

Parasolid Text Files (*.x_t).

SVG Files (*.svg)

CATIA V5 Files (*.CATProduct, *.CATPart).

Pro/ENGINEER Files (*.asm, *.prt).

TSM Files (*.tsm)

DXF Files (*.dxf).

Pro/ENGINEER Granite Files (*.g).

SketchUp Files (*.skp).

Electronics Board Files (*.brd)

Pro/ENGINEER Neutral Files(*.neu).

123D File (*.123dx).

Electronics Schematic Files (*.sch)

Rhino Files (*.3dm).

Creo Parametric Files (*.asm, *.prt).

MACHINING

Centerline Mfg. is equipped to produce everything from simplistic one or two operation products to multi-operation intricate and complex products, in everything from prototype creation to high volume constant production. Alongside our 10-Ton bridge crane over our machining area – we are ready to handle not only the smallest components but, the largest ones as well. Our largest milling envelope is 59”x26.5”x26.5” and our largest turning envelope is Ø21”(SOB)/Ø14.25”(SOCS) x 60”. With an emphasis on quality, Centerline employs industry standard methodology for quality assurance including; Material Certifications, First Article inspections (FAI), First Article Approvals (FAA), and In Process Inspections. Choose an innovative partner that can not only provide quality products but, is also focused on innovative approaches that increase the manufacturability of your products and increase your bottom line.

EQUIPMENT

Mazak

Matsuura

Harrison

Campro

Jyoti

Milltronics

MATERIALS

Mild Steel

Brass

High Strength (HSLA) Steel

Stainless Steel

Galvanized Steel

Aluminum (all grades)

Copper

Various Plastics

Wood Products

VOLUME CAPABILITIES

From prototypes to high volume production into the hundreds of thousands of units annually, depending on complexity,

material and application.

SECONDARY OPERATIONS

Deburring

Hardware Installation

Powder Coating

Catalyst and Non-Catalyst Paints

Heat Treating

Plating

Anodizing

Polishing

DATA EXCHANGE

3D Manufacturing Format (*.3mf)

FBX (*.fbx).

SAT/SMT Files (*.sab, *.sat, *.smb, *.smt)

Autodesk Alias (*.wire).

IGES (*ige, *iges, *igs).

Seimens NX (*.jt)

AutoCAD DWG Files (*.dwg).

NX (*prt).

SOLIDWORKS Files (*.prt, *.asm, *.sldprt, *.sldasm)

Autodesk Fusion Archive Files (*.f3d).

OBJ (*.obj).

STEP Files (*.ste, *.step, *.stp).

Autodesk Fusion Toolpath Archive Files (*.cam360).

Parasolid Binary Files (*.x_b).

STL Files (*.stl).

Autodesk Inventor Files (*.ipt, *.iam).

Parasolid Text Files (*.x_t).

SVG Files (*.svg)

CATIA V5 Files (*.CATProduct, *.CATPart).

Pro/ENGINEER Files (*.asm, *.prt).

TSM Files (*.tsm)

DXF Files (*.dxf).

Pro/ENGINEER Granite Files (*.g).

SketchUp Files (*.skp).

WELDING

Centerline Mfg. employs a wide variety of welding processes to ensure that we can meet a variety of our customers’ needs. With staff experienced in and equipped for; Flux core (FCAW), MIG (GMAW), Pulse MIG (GMAW-P, manual and robotic) and TIG (GTAW) – alongside Centerline’s (3) 10-Ton bridge cranes; there is no weldment too small or too big.

EQUIPMENT

Millers

L-Tecs

Lincolns

Miller AU260 PerformArc 2200SS

MATERIALS

Mild Steel

High Strength (HSLA) Steel

Stainless Steel

Galvanized Steel

Aluminum (all grades)

VOLUME CAPABILITIES

From prototypes to high volume production into the hundreds of thousands of units annually, depending on complexity,

material and application.

SECONDARY OPERATIONS

Deburring

Tapping

Machining

Hardware Installation

Powder Coating

Catalyst and Non-Catalyst Paints

Heat Treating

Plating

Anodizing

Polishing

DATA EXCHANGE

3D Manufacturing Format (*.3mf)

FBX (*.fbx).

SAT/SMT Files (*.sab, *.sat, *.smb, *.smt)

Autodesk Alias (*.wire).

IGES (*ige, *iges, *igs).

Seimens NX (*.jt)

AutoCAD DWG Files (*.dwg).

NX (*prt).

SOLIDWORKS Files (*.prt, *.asm, *.sldprt, *.sldasm)

Autodesk Fusion Archive Files (*.f3d).

OBJ (*.obj).

STEP Files (*.ste, *.step, *.stp).

Autodesk Fusion Toolpath Archive Files (*.cam360).

Parasolid Binary Files (*.x_b).

STL Files (*.stl).

Autodesk Inventor Files (*.ipt, *.iam).

Parasolid Text Files (*.x_t).

SVG Files (*.svg)

CATIA V5 Files (*.CATProduct, *.CATPart).

Pro/ENGINEER Files (*.asm, *.prt).

TSM Files (*.tsm)

DXF Files (*.dxf).

Pro/ENGINEER Granite Files (*.g).

SketchUp Files (*.skp).

FINISHINGS/COATINGS

/HEAT

TREATING

Regardless of our customers’ need(s) for the last step in their product or components fabrication, Centerline Mfg. has well-established relationships with local vendors to provide our customers their finished goods in the lead times they require.

MATERIALS

Mild Steel

High Strength (HSLA) Steel

Stainless Steel

Galvanized Steel

Aluminum (all grades)

Brass

Copper

Various Plastics

Wood Products

VOLUME CAPABILITIES

From prototypes to high volume production into the millions of units annually, depending on complexity, material and

application.

OPERATIONS

Powder Coating

Catalyst and Non-Catalyst Paints

Heat Treating

Plating

Anodizing

Polishing

DATA

EXCHANGE

3D Manufacturing Format (*.3mf)

FBX (*.fbx).

SAT/SMT Files (*.sab, *.sat, *.smb, *.smt)

Autodesk Alias (*.wire).

IGES (*ige, *iges, *igs).

Seimens NX (*.jt)

AutoCAD DWG Files (*.dwg).

NX (*prt).

SOLIDWORKS Files (*.prt, *.asm, *.sldprt, *.sldasm)

Autodesk Fusion Archive Files (*.f3d).

OBJ (*.obj).

STEP Files (*.ste, *.step, *.stp).

Autodesk Fusion Toolpath Archive Files (*.cam360).

Parasolid Binary Files (*.x_b).

STL Files (*.stl).

Autodesk Inventor Files (*.ipt, *.iam).

Parasolid Text Files (*.x_t).

SVG Files (*.svg)

CATIA V5 Files (*.CATProduct, *.CATPart).

Pro/ENGINEER Files (*.asm, *.prt).

TSM Files (*.tsm)

DXF Files (*.dxf).

Pro/ENGINEER Granite Files (*.g).

SketchUp Files (*.skp).

Electronics Board Files (*.brd)

Pro/ENGINEER Neutral Files(*.neu).

123D File (*.123dx).

Electronics Schematic Files (*.sch)

Rhino Files (*.3dm).

Creo Parametric Files (*.asm, *.prt).

ASSEMBLY

Centerline

Mfg. provides assembly services to their customers, allowing them to receive

their products finished through to the stage they necessitate at their facility,

or we will even dropship to their end users for them. The final step in the end-to-end

manufacturing service that Centerline provides its customers, from hardware

installation to kitting to complete assembly buildouts.

VOLUME

CAPABILITIES

From prototypes to high volume production into the millions of units annually, depending on complexity, material and application.

DATA

EXCHANGE

3D Manufacturing Format (*.3mf)

FBX (*.fbx).

SAT/SMT Files (*.sab, *.sat, *.smb, *.smt)

Autodesk Alias (*.wire).

IGES (*ige, *iges, *igs).

Seimens NX (*.jt)

AutoCAD DWG Files (*.dwg).

NX (*prt).

SOLIDWORKS Files (*.prt, *.asm, *.sldprt, *.sldasm)

Autodesk Fusion Archive Files (*.f3d).

OBJ (*.obj).

STEP Files (*.ste, *.step, *.stp).

Autodesk Fusion Toolpath Archive Files (*.cam360).

Parasolid Binary Files (*.x_b).

STL Files (*.stl).

Autodesk Inventor Files (*.ipt, *.iam).

Parasolid Text Files (*.x_t).

SVG Files (*.svg)

CATIA V5 Files (*.CATProduct, *.CATPart).

Pro/ENGINEER Files (*.asm, *.prt).

TSM Files (*.tsm)

DXF Files (*.dxf).

Pro/ENGINEER Granite Files (*.g).

SketchUp Files (*.skp).

Electronics Board Files (*.brd)

Pro/ENGINEER Neutral Files(*.neu).

123D File (*.123dx).

Electronics Schematic Files (*.sch)

Rhino Files (*.3dm).

Creo Parametric Files (*.asm, *.prt).

QUALITY

Quality through precision; Centerline Mfg.’s namesake. By ensuring we implement precise and controlled quality procedures that are designed with intention for each component or assembly, we ensure that when there is a deviation from the standard set, it can be quickly identified, possible corrective actions assessed, corrective measures taken and that data redefined in the quality control policy to avoid further deviations. Through processes and standards such as; Material Certifications, First Article inspections (FAI), First Article Approvals (FAA), and In Process Inspections – we ensure that the proper methodologies are followed, and that our customers can be confident that they have a trusted partner that maintains high quality control standards.