Our Projects

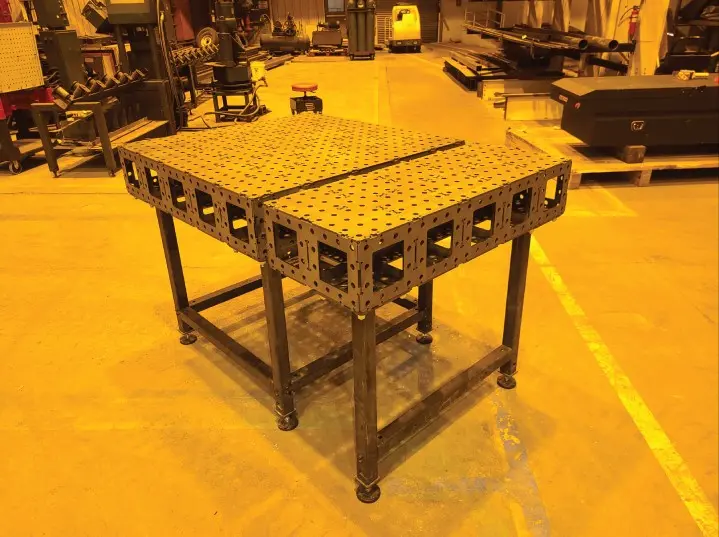

Description:

Material handling rotation tables made to a customer's specifications, able to freely rotate 360°, with machined position stops. Tube material was cut to length, plates were laser cut, and positive stop components were machined. All components were GMAW-P and GMAW welded together.

Description:

Corner Posts welded to customer's specifications for a vinyl fencing application.

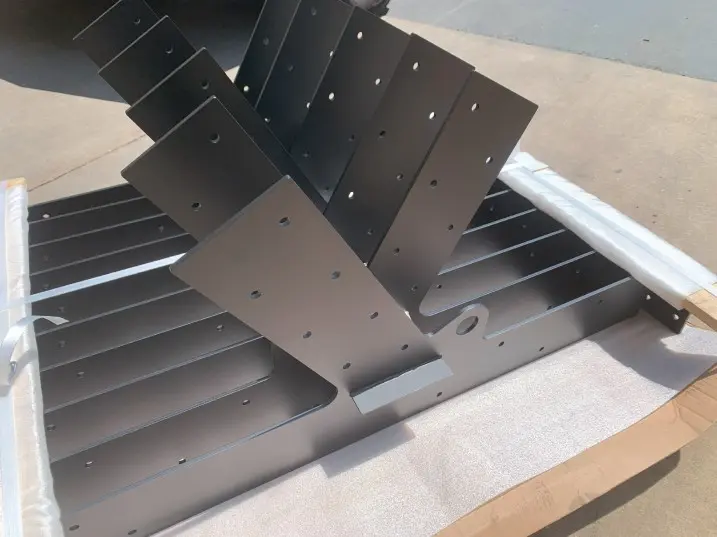

Description:

Laser cut, welded and powder coated brackets for a customer's Safari Tent product line.

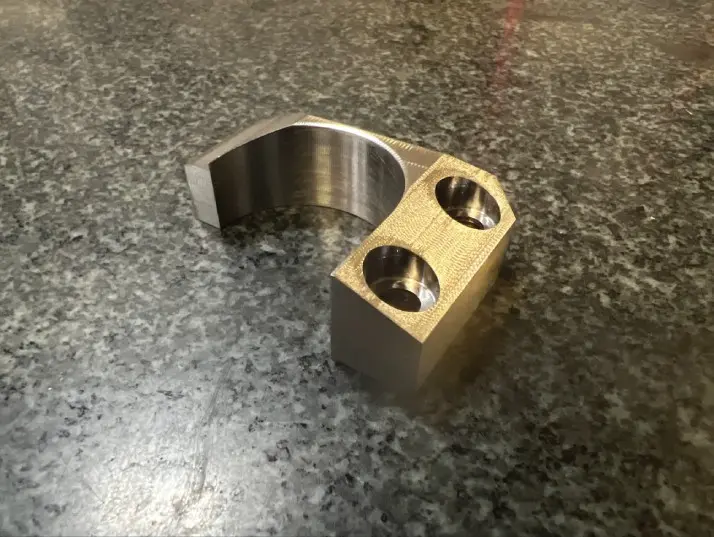

Description:

An equipment component 3D machined from 4140HT.

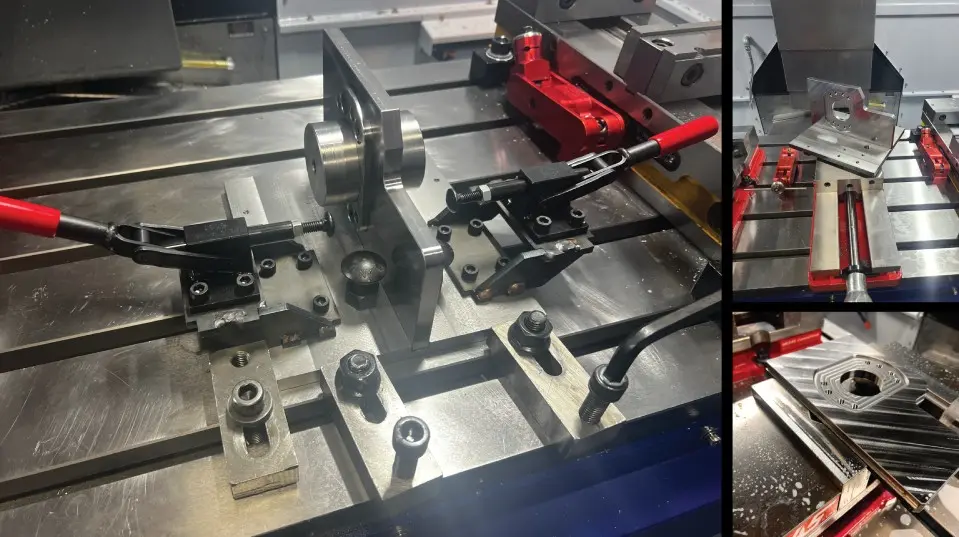

Description:

This fixture was created to handle very high-volume cast part machining.

By delineating what features and components required machined surfaces and

tolerances vs. laser cut tolerances during the design process, this fixture was

able to be completed in time for our next production run and at a lower cost

than had it been completely machined. It is important to be able to determine

the real requirements of the project and have the right equipment readily

available for the job at hand to be able to produce superior components at a

competitive price.

Description:

A series of high precision machined components to be used in

manufacturing equipment. Components were made from various materials,

including; A36, 4140HT and A2.

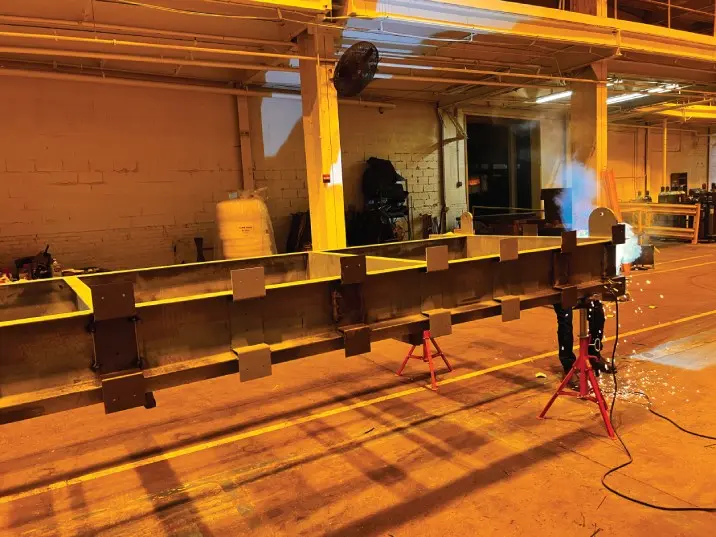

Description:

Fabrication of the structure to a hotel awning.

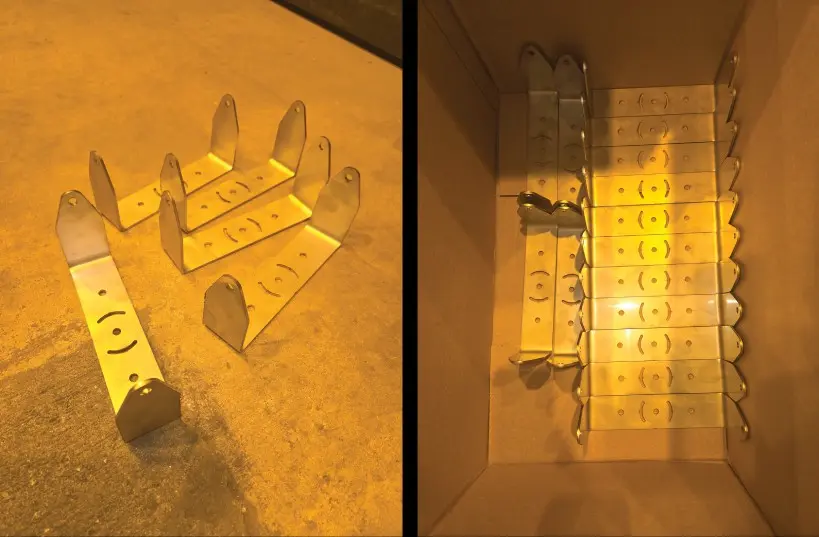

Description:

Laser cut and formed 10ga stainless steel brackets for mounting of a

computer module.